Semiconductor Industry Primer: The Stages of Production and Business Models

Wednesday, Feb 25, 2015, 7:00pm

by Semiconductor Industry Association

[Note: This is part one of a series on the semiconductor manufacturing process and the associated industry business models.]

Often, I am asked by people new to the semiconductor industry how semiconductors are made. While the science and engineering behind how semiconductors are made is akin to modern day alchemy and the process is quite complicated, I try to answer this question by outlining the three basic stages of semiconductor production and describing how semiconductor firms choose to participate in this production process.

Semiconductor firms generally organize their activities around the following three distinct stages of semiconductor production, or fabrication. Generally speaking, the distinguishing factor (though not the only one) among these stages is that they are almost always done in separate physical facilities:

1) Semiconductor Design. Also known as fabless manufacturing, this stage consists of designing semiconductor devices. It is distinct from the latter two stages, in that it does not involve activities in a semiconductor fabrication facility, or “fab”. Hence, why this stage is often referred to as fabless.

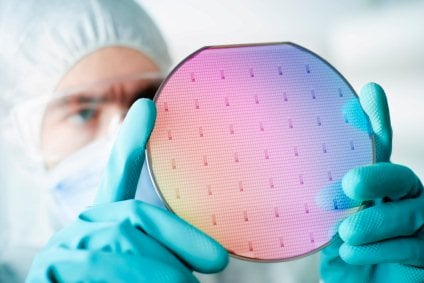

2) Front-end Semiconductor Fabrication. This stage consists of the physical creation, or fabrication, of the semiconductor. This is done in an ultra-clean facility known as a fab. The process involves creating identical semiconductors on ultrapure round silicon wafers using extremely sophisticated equipment, materials, and processes. This stage is highly capital intensive, and leading-edge fabs can cost several billion dollars to construct.

3) Back-end Assembly, Test, and Packaging. Once the front-end fabrication stage is complete, the finished semiconductor wafers are then transported to another manufacturing facility where the third and final stage occurs. This stage, commonly known as back-end assembly, test, and packaging, typically begins when the finished wafer is cut up into individual semiconductor devices, or dies. Each die is then tested with defects discarded and each functioning die packaged into completed semiconductor devices ready for final sale to end customers.

Semiconductor companies have chosen to participate in these stages of production in a variety of ways, giving rise to an assortment of business models. I’ll cover these models in more detail in future posts.